The Basics of Heating Elements

Grasping the Fundamentals of Heat Generation

Heating elements are the unsung heroes in electric kettles, responsible for transforming electrical energy into heat to boil water efficiently. They serve as the core component that enables electric kettles to function with such proficiency. To create the necessary heat, these elements typically consist of materials and alloys with high resistance and thermal conductivity, such as nickel-chromium or stainless steel.

The process begins when an electrical current passes through the heater's resistance wire. This resistance generates heat, causing the element to reach high temperatures. Different heating methods include cartridge heaters, open coil heaters, and thick film technologies. Each plays a unique role in determining the overall performance and efficiency of an electric kettle.

Moreover, the effectiveness of a heating element is influenced by its watt density, which refers to the amount of heat produced per unit area. Elements with higher watt densities can heat water more quickly, however, they must be carefully managed to prevent overheating or uneven temperature distribution.

Understanding how these elements work sets the foundation for exploring the range of types available, as well as their efficiency and performance characteristics. Knowledge of the heating process is also essential for troubleshooting common issues and receiving free shipping on replacement free shipping heating elements from reputable sellers. For further insights into the advantages of temperature adjustable kettles, visit Benefits of a Temperature Control Water Kettle.

Types of Heating Elements in Electric Kettles

Discovering Various Heating Mechanisms in Electric Kettles

Electric kettles rely on different heating components to reach their perfect boiling point. Understanding these mechanisms can enhance the user's ability to select a kettle tailored to their needs.- Resistance Wire Heaters: The most common type found in electric kettles. Typically made from nickel chromium alloys, these wires have a high-temperature coefficient, allowing them to convert electrical current into heat quickly and efficiently. This resistance wire is often embedded within the base of the kettle, generating the thermal energy required to raise water temperature.

- Ceramic Heating Elements: Known for their durability, ceramic heaters offer efficient heat distribution. Used in high-end kettles, these elements are favored due to their ability to withstand high temperatures without deterioration. Their thermal retention capabilities often lead to energy savings.

- Thick Film Heaters: A newer technology that uses a thin, laminated surface applied to a substrate. These elements heat up rapidly, providing quick temperature adjustments. They are also energy-efficient due to their high watt density, saving both time and electrical consumption.

- Silicone Rubber Flexible Heaters: These heaters offer a flexible design, allowing them to be molded to the kettle's shape for uniform heating. Their adaptability makes them a popular choice for advanced kettle designs requiring consistent temperature management.

- Carbide Heating Elements: Utilizing silicon carbide, these elements provide substantial heating capabilities. They are known for withstanding exceptionally high temperatures, making them suitable for kettles needing reliable performance under rigorous conditions.

- Stainless Steel Coil: Though more traditional, these open-coil elements are still widely used. Stainless steel offers resistance to rust and corrosion, making it a reliable choice for longer-lasting electric products.

Efficiency and Performance of Heating Elements

Evaluating Efficiency and Enhancements in Heating Elements

Electric kettles depend heavily on their heating elements for efficiency and performance. When exploring different elements, two factors are critical—their ability to transfer heat and their resilience under high temperatures. Efficiency is primarily achieved through minimizing heat loss and maximizing energy transfer.

The use of advanced materials such as nickel chromium and silicon carbide exemplifies this efficiency. Nickel chromium, common in resistance wire settings, is chosen for its high temperature tolerance and durability, making it an excellent choice for consistent heating performance. Similarly, silicon carbide heating elements are recognized for their high thermal conductivity and resistance, offering dependable performance in high temperature applications.

Moving beyond traditional setups, flexible heaters and thick film technology showcase significant innovations in improving heating element efficiency. With their electrically conductive material properties, these heaters ensure thermal consistency and can be molded into various product designs, aligning with modern demands for space-saving and high watt density elements.

Film heaters specifically highlight the use of advanced ceramics and flexible silicon rubber substrates, harnessing electrical resistance to produce heat evenly across the surface. In contrast, open coil and cartridge heaters offer quick and robust thermal responses, often paired with stainless steel pipes for a reliable temperature coefficient.

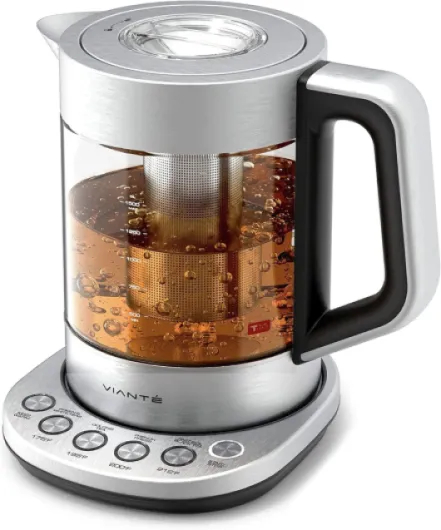

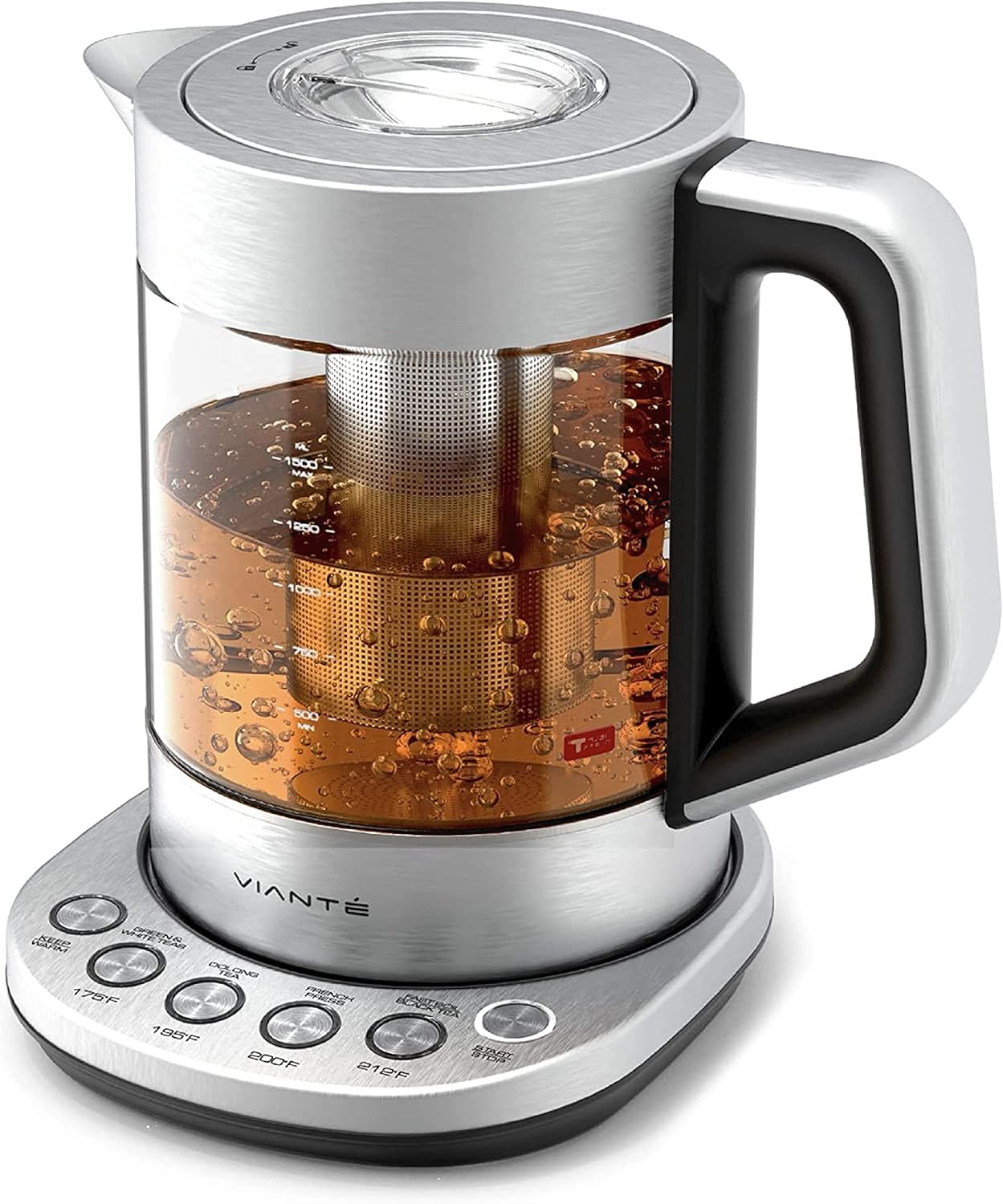

While engineering advances enhance performance, effective use of control panels can significantly influence how heating elements operate with optimal results. A precise temperature management system helps in choosing an electric tea maker that matches specific user needs. Understanding the implications of temperature settings and control interfaces remains vital for consumers aiming to tap into the best performance from their electric kettle’s heating unit.

Common Issues with Heating Elements

Understanding Potential Challenges with Heating Components

Electric kettles are highly efficient, yet the heating elements inside them can face challenges that may impact performance and longevity. Recognizing common issues can help ensure consistent and reliable functionality. The most frequent troubles with heating elements arise from their constant exposure to high heat and thermal cycling. The heating elements, whether they are constructed from nickel chromium alloys or silicon carbide, endure significant wear and tear. Over time, resistance wire components may become brittle or develop hot spots that can lead to failure. This is particularly common with open coil and resistance wire designs, where uneven heat distribution might lead to premature burnout. Ceramic and thick film heaters, while resilient to some extent, are not immune to the buildup of limescale and mineral deposits, especially in areas with hard water. This accumulation interferes with the heating process by creating insulation that hinders direct contact between the water and the heating element, thereby increasing energy consumption and reducing the element's efficiency. Flexible heaters and silicone rubber elements are less prone to mechanical failure, but their insulating material might degrade over time if exposed to extreme temperatures beyond their specified thermal tolerance. Ensuring these components remain within their designed temperature coefficient is crucial for maintaining their effectiveness. Cartridge heaters and film heaters are often utilized when precise temperature control is required, but they require consistent maintenance and monitoring to avoid overheating or electrical issues. Any degradation in the electrical insulation of these components can lead to performance issues or, in the worst case, electrical failures. To counteract these issues, appropriate troubleshooting and routine maintenance practice needs to be implemented, ensuring the longest life possible for electric kettle heating elements. Regular cleaning of mineral deposits, timely replacement of faulty parts, and monitoring watt density to prevent overheating are essential steps in maintaining the efficiency and reliability of your electric kettle.Maintenance Tips for Long-lasting Heating Elements

Maintaining Your Heating Elements for Lasting Use

The longevity and efficiency of electric kettle heating elements largely depend on proper maintenance. Here are some practical tips to ensure your kettle performs at its best over time:- Regular Descaling: Mineral build-up can significantly impact the effectiveness of heating elements. Regular descaling combats limescale, especially if your water is rich in minerals. Use products designed for electric kettles to preserve the integrity of materials like stainless steel.

- Avoid Dry Boiling: Always ensure the kettle has water before turning it on. Dry boiling can damage the resistance wire and the inner coatings of heating elements like silicon carbide or nickel chromium.

- Temperature Control: Some kettles come with control panels that allow precise temperature settings. Adjusting the heat to avoid unnecessary high temperatures can help extend the life of both thick film heaters and flexible heaters.

- Inspect for Wear: Regularly inspect your kettle for signs of wear, such as discoloration or damage to the resistance wire and thermal elements. Early identification of issues can prevent more serious problems.

- Proper Storage: Store your kettle in a dry place and ensure it's clean before storing it after use. This helps maintain the integrity of open coil and cartridge heaters, especially if they are made from materials susceptible to corrosion.